Nyrstar Belgium wants to be one of the world’s zinc smelters with the lowest CO2 footprint by 2023. Energy experts Philip Eyckmans and Thomas Verbruggen talk about how Nyrstar is planning to do this.

The Nyrstar zinc smelters in Balen and Pelt are powered almost solely by electricity. That is where the great battle for sustainability can be won. A lot of work has already been done in terms of heat recovery.

‘Ninety per cent of the heat that we need is generated by ourselves during the first step of our production process after we have used it to produce five megawatts of electricity first,’ says Philip Eyckmans, global category manager energy at Nyrstar. But this heat in itself cannot generate the huge amount of electricity required by the zinc smelter (more than one per cent of the total consumption in Belgium).

That is why Nyrstar makes its sites and infrastructure available for sustainable energy projects from which it can also reap the benefits. ‘We produce hardly any CO2 emissions ourselves. If we succeed in making our electricity production completely renewable, we will be almost CO2-neutral.’

Ninety per cent of the heat that we need is generated by ourselves during the first step of our production process.

Philip Eyckmans,

global category manager energy for Nyrstar

Renewable energy

Thanks to the nearby Kristal Solar Park in Lommel, the solar park in Pelt and the wind turbines at and around the Balen and Pelt sites, currently approximately 11 per cent of the energy that we use on an annual basis is renewable.

‘We benefit from up to of 121 megawatts of locally generated renewable energy for our sites in Balen and Pelt’, says Thomas Verbruggen, energy coordinator European operations at Nyrstar. ‘Those figures should be higher by the end of 2021. The wind turbines are being replaced and four new ones are to be added in Balen and three in Pelt.’

However, it is going to take a while to become 100 per cent self-sufficient in terms of green energy. ‘We consume 1.1 million megawatt hours per annum. We cannot produce that much ourselves at the moment but that is our aim. Until we are able to do that, we will keep on buying green electricity’, says Verbruggen.

As a result of its purchasing behaviour, half of the operations at Nyrstar Belgium currently run on renewable

energy. However, the plant in Budel, a similar plant just over the Dutch border, runs solely on renewable electricity. 'A conscious choice’, says Verbruggen. ‘There are still coal-fired power plants in the Netherlands, so the electricity that is supplied as standard to the market has a higher level of CO2 emissions.’

Today, our plants in Balen and Pelt run 50 per cent on renewable energy.

Thomas Verbruggen,

energy coordinator European operations for Nyrstar

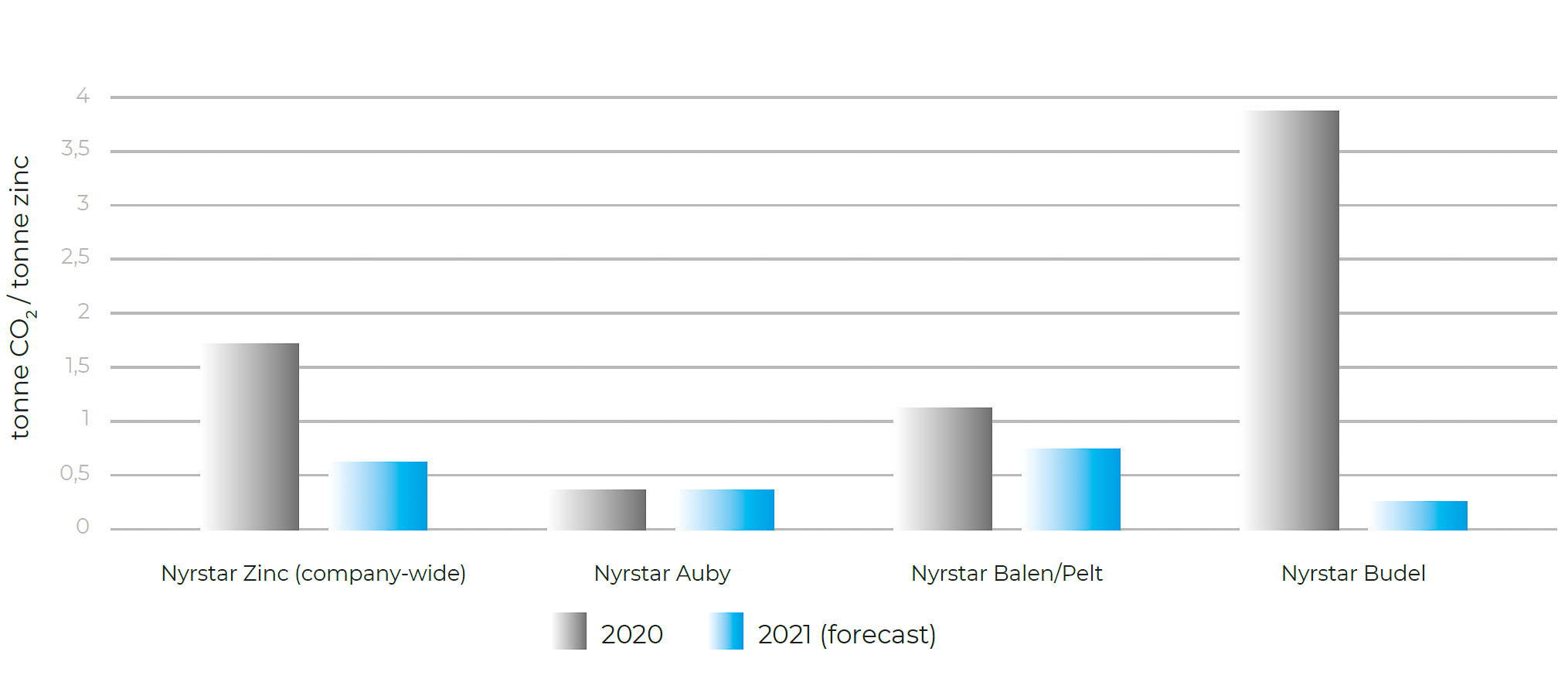

By making such choices, Nyrstar’s level of greenhouse gas emissions this year will be 50 per cent lower than it was in 2020. A result that is in line with the CO2 targets of majority owner Trafigura: to reduce global emissions by 30 per cent by 2023.

Train and boat

Transport is also being considered in connection with reducing the ecological footprint. ‘We are well-located.

Our primary raw materials arrive by seagoing vessel in Antwerp. From there, they are taken by train to Balen and Budel and via the inland waterways to Auby, our branch in northern France. The secondary raw materials mainly come from Europe’, says Eyckmans.

The end products are transported to the customer by truck. ‘But the distances involved are never huge. Our European smelters are nicely spread out and our customers are never far away.’ In order to reduce the freight transport footprint, Nyrstar offers the option of compensating for the emissions produced by such transport via parent company Trafigura.

Circular

Finally, Eyckmans adds that zinc fits in perfectly with a circular economy. ‘The inherent recyclability of zinc makes it an important raw material. A lot of the world’s refined zinc is simply reused.’

The big challenge lies in getting it back. ’Steel structures are extremely durable. We are currently recycling zinc that was first used fifty years ago. That shows how durable zinc is.’

4 recipes for a sustainable supply chain

7,200 truck journeys taken off the road

In May 2021, Nyrstar entered into an agreement with terminal operator SEA-invest to expand the storage facility at the Port of Antwerp and enable even more transportation by rail. ‘By doing this, we will take 7,200 truck journeys from Budel to Antwerp off the road per annum’, says Ricardo Paulo, global head logistics at Nyrstar.

20 per cent more raw materials via inland waterways

Today, tons of goods are transported between the Port of Antwerp and the Nyrstar plants via the inland waterways or by rail and no longer by road. On some routes, transport by road has dropped by 95 per cent. In addition, 20 per cent more raw materials are transported using inland vessels.

1.6 million euros for new hub

In 2020, Nyrstar invested 1.6 million euros in a logistics hub for the European distribution of zinc oxides (recycled zinc) at its site in Pelt.

Green fuel

‘Our objective is to always choose the greenest form of transport and that goes for our trucks too’, says Ricardo Paulo. ‘We are currently looking at green fuels among other things.’