Zinc is one of the base metals with the lowest CO2 footprint, and plays an important role in the energy transition. ‘A 10-megawatt (MW) onshore solar farm contains 24 tonnes of zinc’, states Martin van Leeuwen from the International Zinc Association.

To achieve a CO2-free future, the world needs not only smart technologies and collaboration projects, but also sustainably mined and produced metals. Zinc plays an important role here. The blue-grey metal is to be found, for example, in rechargeable batteries in data centres, in home battery storage systems and in renewable energy storage systems.

The development of rechargeable zinc batteries is moving fast. In the United States alone, 200,000 homes have already been equipped with zinc-based battery storage systems.

Greening energy production

‘Solar panel installations and wind turbines also contain a lot of zinc’, explained Martin van Leeuwen, director of technology and market development at the International Zinc Association (IZA). ‘The structure of a 44-MW solar farm, such as the solar farm located at Nyrstar Budel in the Netherlands, contains about 106 tonnes of zinc, while the 752-MW Borssele I & II offshore wind farm along the Westerschelde estuary contains about 300 tonnes of zinc. Zinc coatings protect the steel in wind turbine towers and solar panel structures from corrosion. With the service life of these coatings extending well beyond

Zinc recycling is growing much faster than zinc ore mining.

Martin van Leeuwen,

Director of Technology and Market Development at the International Zinc Association (IZA)

that of the plants themselves, little to no corrosion maintenance is required. ‘That saves money, materials, transportation and thus CO2 emissions.’

Zinc producers can further reduce the CO2 footprint of their products by opting for renewable energy sources in their energy mix. ‘In zinc mining, all machinery, transport and processing facilities can be electrified, theoretically eliminating the need for fossil fuels’, emphasized Martin van Leeuwen. ‘Smelting concentrates to zinc is usually done via an electrolysis process - as is the case at Nyrstar's smelters - requiring little to no fossil fuels. This is thus a very efficient and environmentally friendly approach.’

Urban mining

Recycling also plays a key role. Paris is full of titanium zinc roofs. With their lifespan of up to a hundred years now exceeded, this zinc is remelted into new zinc products after removal. ‘Titanium zinc can be almost 100 percent recycled.’

‘Even zinc from batteries, galvanic coatings, electric cars and just about any other application can be recycled into new zinc at the end of the useful life of these products, without any loss of quality.’

Some 247 million tonnes of zinc are contained in products currently in circulation. These so-called ‘anthropogenic zinc reserves’ or ‘urban mines’ will one day be available for recycling.

‘While zinc recycling is growing much faster than zinc ore mining', noted Martin van Leeuwen, ‘future demand for zinc cannot be met by recycled zinc alone, simply because there is not yet enough zinc available through urban mining. The zinc now being recycled was produced more than 50 years ago.’

Rising demand for zinc

Global demand for zinc is currently around 20 million tonnes a year, though the energy transition is set to increase this by 0.7 to 1.5 million tonnes a year by 2030. But that's no great problem. The world has 250 million tonnes of zinc reserves in the ground. In addition, there are 63 billion tonnes of zinc in the ground that are not currently economically extractable, but are set to become so due to new technological developments.

In the United States alone, 200,000 homes have already been equipped with zinc-based battery storage systems.

Martin van Leeuwen,

Director of Technology and Market Development at the International Zinc Association (IZA)

All metals are needed

As part of the production of zinc from zinc ore, other valuable metals such as copper, lead, nickel, cobalt, germanium and indium are also extracted. Copper is a key metal for the electrification of our society, while lead, nickel and cobalt are the main components of batteries. For the production of germanium and indium, zinc ores are the main and often only raw material.

‘Germanium is essential for producing fibre optics for high-speed Internet, while indium is indispensable for the production of LCD panels and televisions. It is also used in soldering materials for electronic devices and in solar panels.’

Demand for these metals is set to increase in the coming decades, with nearly all of them playing a crucial role in the production, transmission and storage of renewable electrical energy. ‘Zinc will not be replaced by any other metal any time soon’, concluded Martin van Leeuwen, ‘although we need all metals, each with its own unique properties.’

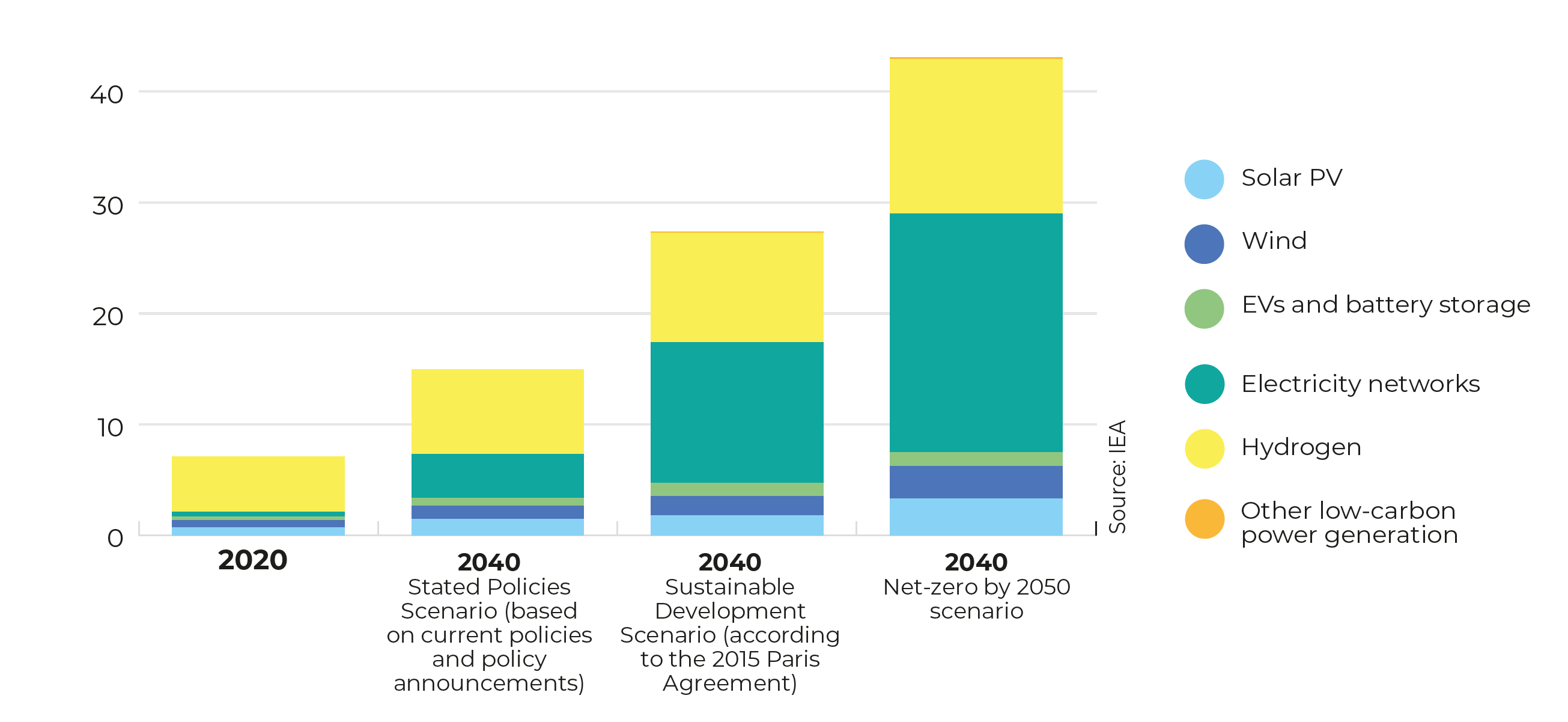

Total mineral demand for clean energy technologies 2020-2040

(million tonnes)